Case Study

- Dorayaki Machine

- Dorayaki

Kuraya Co., Ltd.

Kuraya was founded in 1880, during the early years of the Meiji era, when its first records became available. The store was established by Emi Sogoro, who relocated it to the city center in the early Meiji period. Over the course of four generations, the family trained in Kyoto and earned a strong reputation. For over 100 years, Kuraya became known for its signature sweets, such as Matsu no Tsuyu, inspired by morning dew on pine trees at the castle ruins, Ichima, reminiscent of an Ichimatsu Japanese traditional doll’s dimples, and Shuraku Gaso, named after Shurakuen, a garden in the former Tsuyama domain villa.

Inaba Shinji, the fifth president, took over the store after the bubble economy collapsed, which led to a decline in gift demand. In response, the company shifted its focus to daily-use sweets, including those baked fresh every morning to be sold the same day, and introduced freshly made dorayaki, which became a big hit. The success prompted them to invest in an automatic baking machine. From there, Kuraya continued to innovate, refining their daily offerings, including freshly baked goods made each morning for same-day sale, as well as high-quality confections, while adapting their signature sweets to suit modern tastes.

In addition to running Kuraya, the company has played a key role in tourism and local revitalization efforts. Notably, the Tsuyama Roll, created to promote locally grown Tsuyama wheat, was launched as a joint project by the local confectionery association, with many stores participating. By 2024, over 70,000 rolls had been sold across all stores. Beginning in 2023, the store’s Momotaro Dorayaki will also use 100% Tsuyama-grown wheat.

In the spring of 2024, Kuraya doubled its dorayaki production capacity with an updated production line that includes automated bean paste filling and branding processes. As part of their 140th-anniversary celebrations, they introduced a new mission: “We’re glad Kuraya exists! Declaration,” aiming to provide customers with the joy of discovering sweets and the charm of the region. Their goal is to create a store that people will cherish for the next 100 years, building on the legacy of generations of customers.

Location:77-7 Numa,Tsuyama-shi,Okayama-ken

URL:https://www.kuraya.jp/

Publication:MASDAC news October issue in 2024

Full Automatic Dorayaki Machine(SDR-KAM-16GD)

In 1996, Kuraya introduced an Automatic Dorayaki Machine capable of producing 800 pieces per hour to streamline the baking of dorayaki. With the rise in demand for dorayaki since the pandemic, and in anticipation of further production increases, the machine was upgraded this year to a Full Automatic Dorayaki Machine that can produce 1,600 pieces per hour, including automatic filling of the bean paste. Previously, the bean paste filling and branding processes were done by hand, which posed challenges in terms of productivity and business efficiency. By incorporating this Full Automatic Dorayaki Machine, Kuraya has reduced the number of staff required for production from three to one, while boosting productivity by six times. With a more relaxed production schedule, skilled craftsmen are now able to focus on other specialized tasks. The addition of top heating, which was not available before, also results in a fluffier dorayaki, improving the overall quality. Many customers have noted that the dorayaki tastes even better, and sales have seen a corresponding increase. Looking ahead, Kuraya plans to continue refining its product development and production processes to meet growing demand.

-

Kura Dora made with bean paste from Bitchu Dainagon red beans. Momotaro Dorayaki with Tsuyama wheat batter, filled with red bean paste and millet mochi. 178 Dora featuring the classic Kura Dora branding.

-

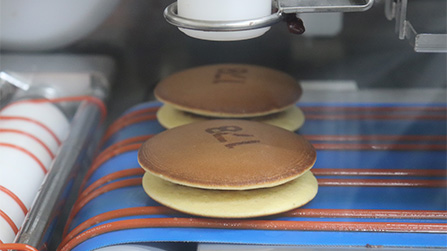

The Full Automatic Dorayaki Machine producing multiple varieties of dorayaki.

-

Production of the limited edition 178 Dora. The “178 (Inaba)” branding is a playful nod to the president’s name.

-

Nama Dora filled with fresh cream and bean paste. Chocolate Dora with chocolate cream. Amanatsu Dora, a seasonal limited edition.

Reference

MASDAC NEWS trial version

Case studies are published in our PR magazine MASDAC NEWS delivered to users. In the magazine, we present various information related to sweets and food manufacturing, including an interview with our customers’ top management. Here, you can check out the trial version of the magazine. For periodical delivery of the MASDAC NEWS in a printed format, please send us a request via the following request form.

View the Trial Version (PDF)